Foil technology

Foil technology

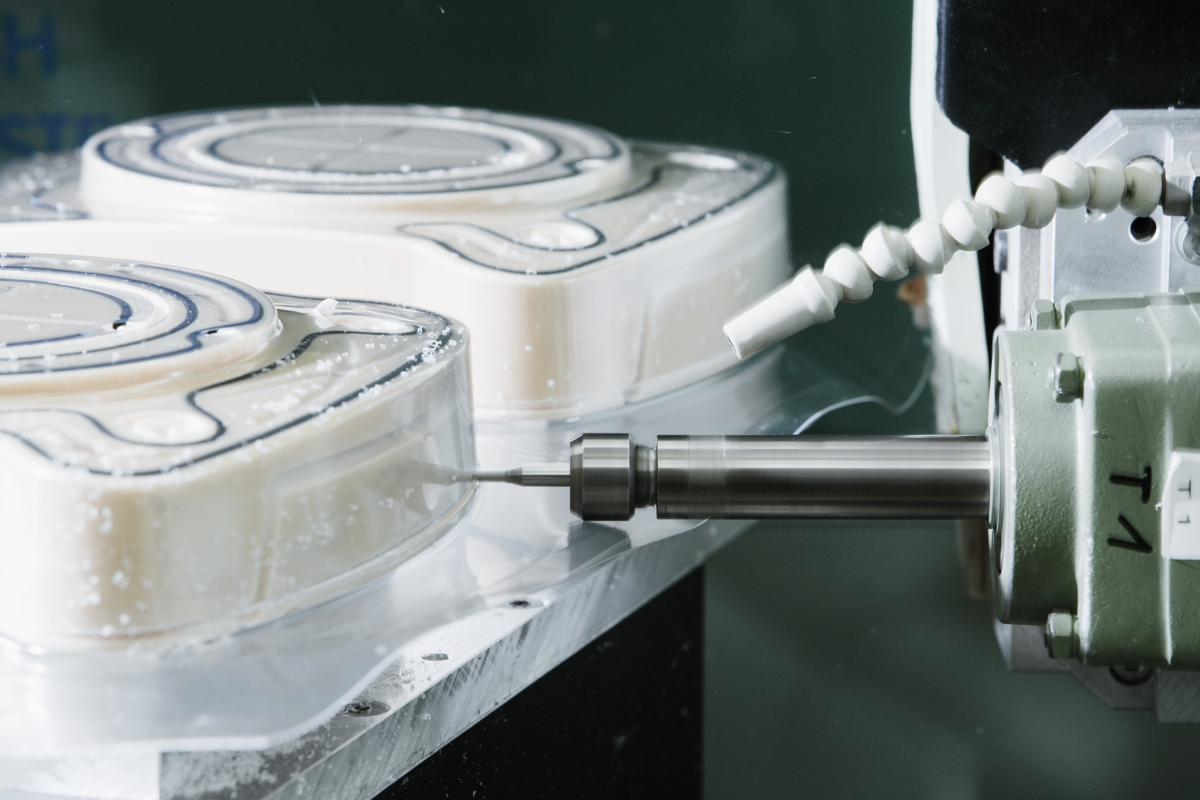

The foil technology department creates tailor-made products to suit your application. By combining technology, materials and know-how, our innovative development team is able to respond to your ideas and turn them into high-quality products. We are able to put fillable moulded parts as well as standard products for medical technology, aviation and even sporting applications into series production.

The foil technology department uses these processes: customised foil cutting, thermoforming, punching, high-frequency and thermocompression welding.

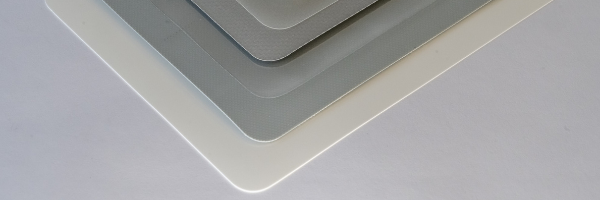

We have foils with specific properties: crystal clear, transparent or coloured, soft, stretchable and flexible or hard, fibre reinforced, highly tear resistant and with glass fleece reinforcement.

Materials

TPU – thermoplastic polyurethane

Elastic and flexible foil

- Excellent elastic properties

- High durability

- High chemical resistance

- Soft and flexible

- Safe for contact with skin

- Antibacterial effect (possible if desired)

Bio-based TPU film

Partly renewable resources

- Polymer raw material from biomass

- Good weather resistance

- High durability

- Excellent abrasion resistance

- Excellent elastic properties

- Positive contribution to the CO2 balance

PET – polyethylene terephthalate

Excellent optical properties

- 100% recyclable

- Chemical resistance

- Excellent mechanical properties

- Heat resistant

- High gloss and transparent

- Positive contribution to the CO2 balance

PVC – polyvinyl chloride

Robust & stable foil

- Resistant to acids, alkalis, ethanol, oil and petrol

- Very light resistant

- Good UV and weather resistance

- Good insulation properties

- High durability

- Low thermal conductivity