Mobility solutions from warning pennants to air cushion systems

Close cooperation with the customer is the decisive factor for successful product development. We take your idea and apply our approaches to finding a solution. Together, we create an individual, precise solution that meets your expectations.

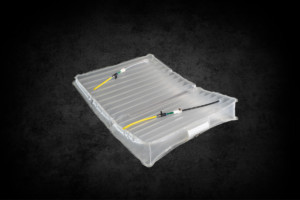

For the mobility sector, we have already been able to work on many interesting projects together with our customers. Complex shaped air cushion systems are created in our production facility for the aviation industry. This is a pneumatically adjustable air cushion system for installation in first and business class aircraft seats. For another customer, we manufacture so-called “Junior Comfort Seats”, which transform the aircraft seat into a comfortable and child-friendly surrounding by means of an air cushion system. At our company headquarters, we also produce warning pennants for truck lifts, custom-made protective covers for parking and fuel terminals and much more.

We assemble products from different materials, shapes and colours – there are hardly any limits. Our project managers are supported by an extensive internal team. From development to prototyping to production, all steps are carried out in-house. Now tell us your vision and we will develop a 360° solution for you!