Construction

Customised plastic components

Our company was created together with the internationally active construction supplier, Sarnafil. Therefore, we have profound experience in structural and civil engineering, and stand for innovative product solutions in the construction industry as well as for holistic, customised, individual solutions.

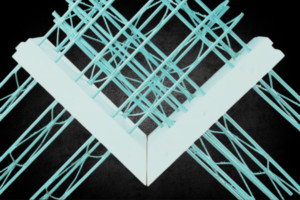

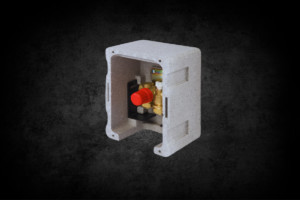

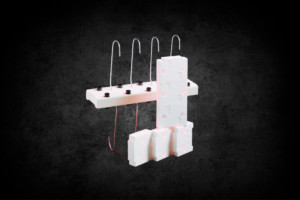

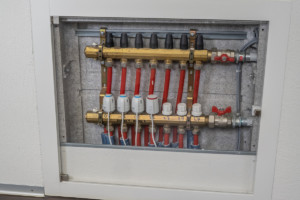

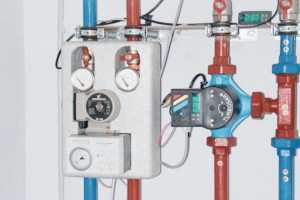

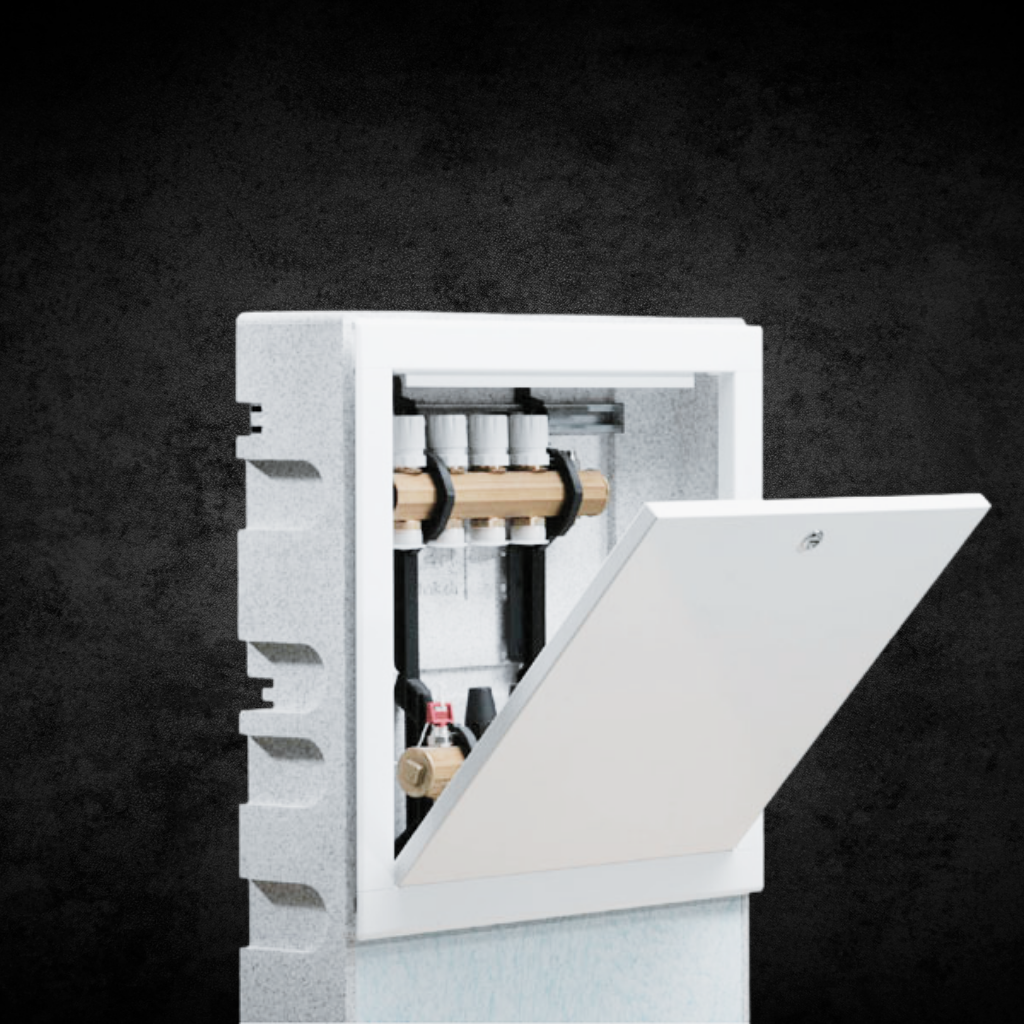

Our solutions are just as diverse and comprehensive as your requirements for plastic construction elements may be. As a result, the scope of delivery of plastic construction elements is very broad – whether standard components or tailor-made creative solutions, we support you with services individually adapted to your needs. For example, good thermal insulation using plastic insulation boards is the most effective measure for ensuring energy-efficient buildings. The results of optimal insulation include a pleasant indoor temperature and lower heating costs. For this purpose, we build using our insulation material – for example, formwork elements and plastic insulation panels that can be used in different parts of buildings such as facades, flat and pitched roofs and walls. In addition, we create plastic construction elements such as cantilever slab connections, hard points, block-out elements, lightweight boards, plinth boxes and distribution cabinets. In the flat roof sector, we manufacture moulded parts such as pole surrounds, outlet pipes and much more.

We use combined and refined foams with a density of up to 410 kg/m3. Functional and reinforcing metal and plastic components are foamed in during the production process. Our flame-retardant EPS material ensures a high level of fire protection.

BUILDING EXCELLENCE

WE EMERGED FROM THE SARNA GROUP

Flame-retardant EPS

as insulation material

1. Flame retardant

2. Protects from fire spread

3. Does not release toxic gases

4. High density freedom

5. High tensile strength

6. High impact strength

7. High stability

8. Excellent compressive strength

9. Saves energy cost

10. Breathable

1. Flame retardant

2. Protects from fire spread

3. Does not release toxic gases

4. High density freedom

5. High tensile strength

6. High impact strength

7. High stability

8. Excellent compressive strength

9. Saves energy cost

10. Breathable

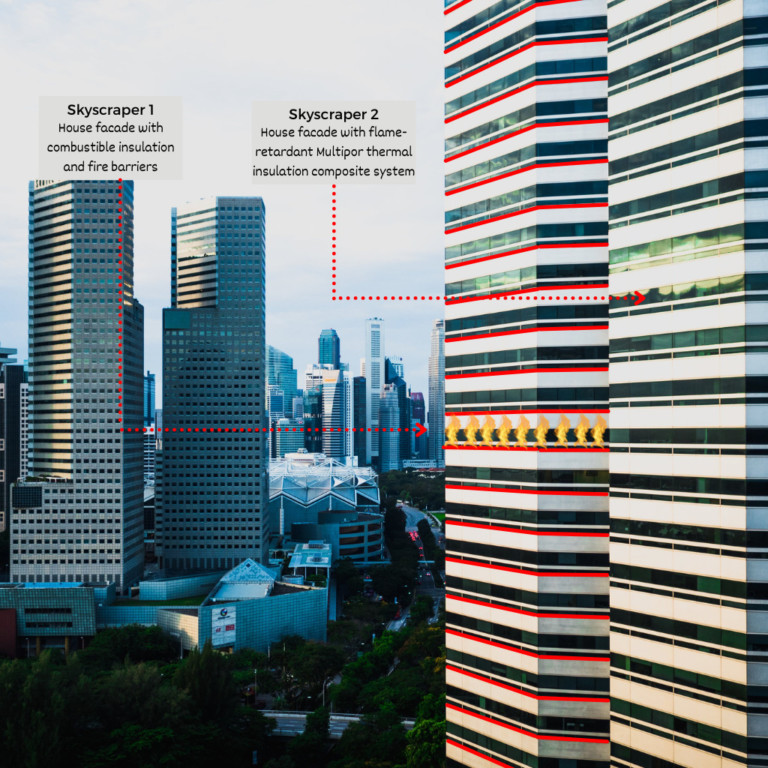

Flame-retardant Multipor thermal insulation composite system for plastic insulation panels

Problem

The biggest fires in the new millennium remain in our memories. One of them is the Grenfell Tower disaster in London on 14 June 2017. 72 people lost their lives in the 24-storey building.

In the recent large-scale fires, many people died from asphyxiation or toxic gases. For this reason, the search for economical and effective insulation and fire protection solutions must continue.

Solution

What customers say