Foam technology

Foam technology

Together with you, the foam technology team creates high-quality EPS packaging or EPP packaging from particle foam. We shape your product requirements into sustainable foam solutions by combining design, materials and technology. Supported by our broad and versatile materials portfolio, we create the optimum moulded part for every application, taking into account the highest quality standards, and there are virtually no limits in terms of design freedom.

Our foam technology has foams, with specific properties, entirely tailored to your intended use: soft as a cushion, hard as wood, flame retardant, antistatic, conductive, coloured or bio-based.

Materials

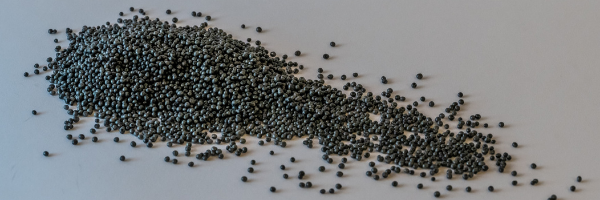

rEPS – recycled EPS

EPS made from up to 100% recycled material

- 100% recycled EPS

- Positive contribution to CO2 balance

- Heat and noise insulating

- Antistatic possible (ESD packaging)

- Flexible design options

- High density freedom

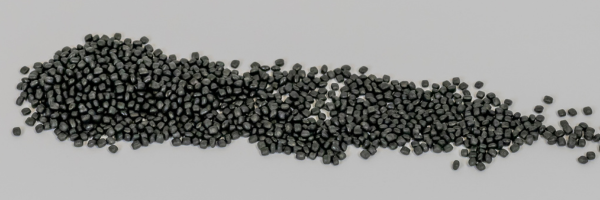

rEPP - recycled EPP

rEPP packaging made from recycled material

- 90% recycled EPP

- Positive contribution to CO2 balance

- Heat and noise insulating

- Chemical resistance

- Flexible design options

- Excellent multi-shock behaviour

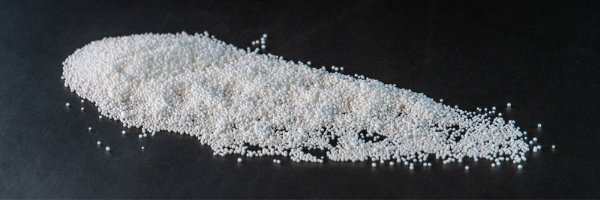

Green Planet

Natural polymer / 100% from biomass

- Bio-based and biodegradable

- Proven certification

- Positive contribution to CO2 balance

- Excellent multi-shock behaviour

- Good thermal insulation properties

- Fire behaviour: self-extinguishing

EPS – expandable polystyrene

EPS packaging/moulded parts made from 98% air

- Heat and noise insulating

- Diffusion-open

- Non-ageing

- Antistatic possible (ESD packaging)

- Flexible design options

- High density freedom

EPP – expandable polypropylene

EPP packaging/moulded parts made from 95% air

- Heat and noise insulating

- Antistatic possible (ESD packaging)

- High density freedom

- High elasticity

- Chemical resistance

- Excellent multi-shock behaviour

EPE – expandable polyethylene

Ideal protection for sensitive surfaces

- Heat and noise insulating

- High density freedom

- Protection for scratch sensitivity

- Antistatic possible (ESD packaging)

- Soft surface

- High elasticity

InSphere

Hard and dimensionally stable components

- Heat and noise insulating

- Good mechanical properties

- Non-ageing

- Very high density freedom

- High compressive strength

- High surface hardness

Flame-retardant EPS

Optimum fire protection

- Heavy flammability

- Protection against the further spread of fire

- Does not release toxic gases

- High density freedom

- Non-ageing

- Fire behaviour RF2

Lambdalit

Very high densities can be achieved

- Heat and noise insulating

- High strength (cf. injection moulding)

- High density possible from 230 to 410 kg/m3

- Non-ageing

- Resilience

- Fracture strength